Microsoft’s Microfluidic AI Cooling: Turning Chips Into Liquid-Cooled Engines

In the race to power ever more advanced AI, one barrier continues to slow progress.

In the race to power ever more advanced AI, one barrier continues to slow progress:

heat. As chips become more powerful, they generate intense temperatures that traditional cooling systems struggle to manage. Microsoft’s latest move seeks to rewrite this challenge altogether by embedding microfluidic cooling directly into the silicon itself.

Let’s unpack what this new cooling tech means for data centers, AI startups, and the future of computing.

What Is Microfluidic Cooling?

Traditional cooling methods air fans, cold plates, or even immersion cooling work by removing heat through layers of materials and interfaces. That means there’s always some thermal resistance between the chip’s hottest regions and the coolant.

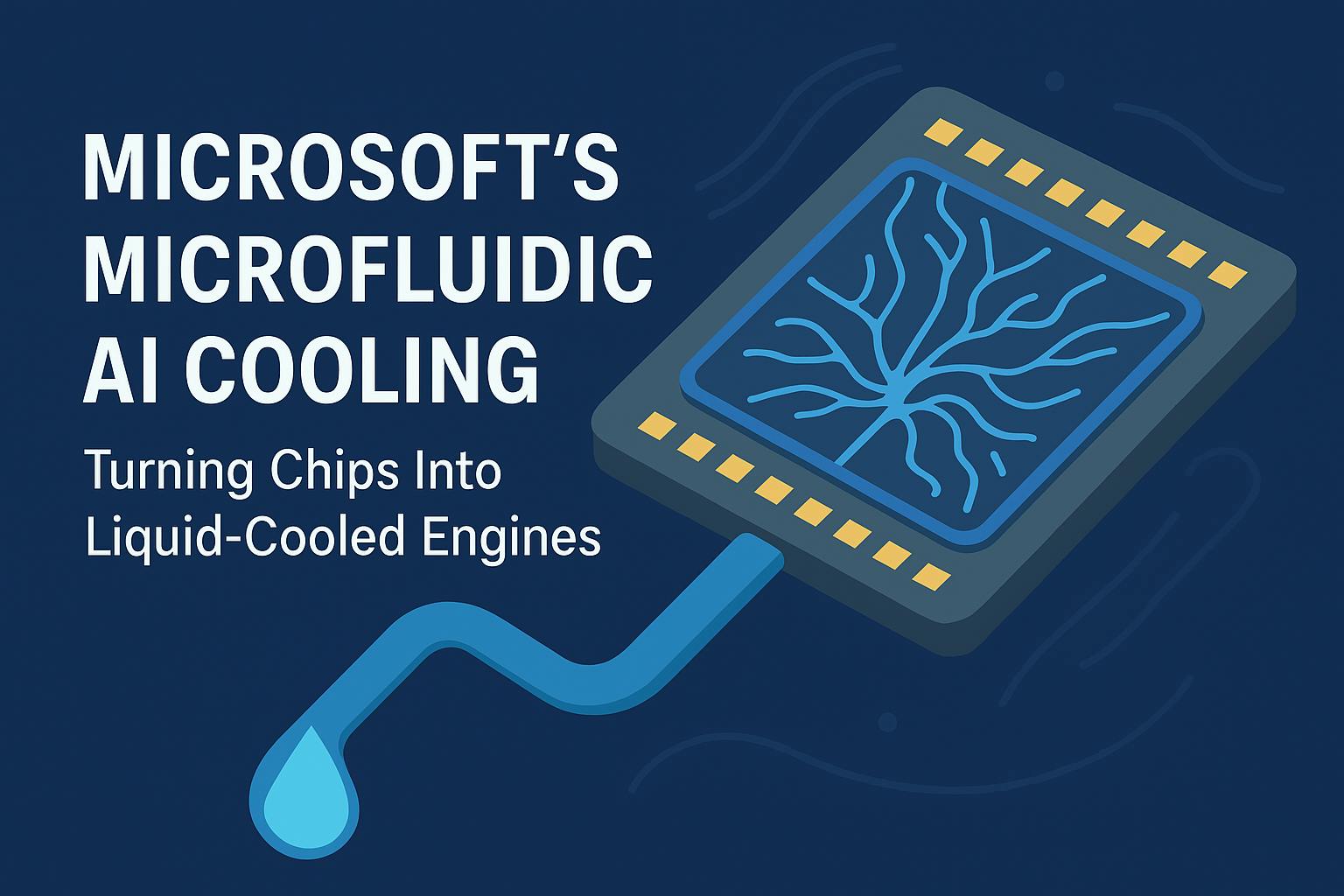

Microsoft’s innovation is different: they etch tiny channels (microfluidics) directly into the backside of the silicon chip. Coolant flows through these channels, bringing it much closer to the heat source. That means a more direct, efficient path for heat removal.

They also use AI techniques to model heat signatures and guide where coolant is most needed, making the design bio-inspired (think veins in leaves) and optimized for each chip’s unique hot zones.

Key Gains & Metrics

Some of the most impressive results from lab tests and early prototypes:

- Up to 3× better heat removal vs. traditional cold plates, depending on workload and chip structure.

- 65% reduction in peak temperature rise in GPU silicon under load.

- Possibility to pack more chips closer together (higher density) without thermal throttling.

- Improved power usage effectiveness (PUE) and lower energy for cooling at the data center level.

Implications for Data Centers & AI Startups

1. More Computing in Less Space

Because chips can be cooled more aggressively, servers can be placed closer together, reducing the footprint needed and lowering latency.

2. Reduced Cooling Costs

Less dependency on large chillers, fans, and external cooling infrastructure means big opportunities to cut operational expense and energy use.

3. Enabling Next-Gen Chip Architectures

One of the traditional obstacles to stacking or 3D chip designs is how to get heat out of the interior layers. Microfluidics gives a way to cool between layers.

4. Opening Innovation for AI Startups

Smaller operations may now dare to design high-power models without being bottlenecked by cooling infrastructure. This levels the playing field.

5. Engineering & Reliability Challenges

This isn’t easy to scale. Channels must be deep enough to carry coolant, but not so deep that they weaken the silicon or risk leakage. Microsoft has already released multiple versions.

How It Fits Into the Bigger Trend

This move by Microsoft is part of a broad shift: co-designing hardware and infrastructure, not treating cooling as an afterthought. They call this a “whole-systems approach” from silicon to servers to data centers.

As AI demands continue to rise, innovations like microfluidic cooling will become crucial. We’ll likely see:

- More companies are trying in-chip cooling

- New materials and fabrication methods

- Cooling systems are optimized alongside chip design, rather than layered on afterwards.

Final Thoughts

Microsoft’s microfluidic cooling is a bold leap. It shows how engineering dilemmas once thought “solved” can still be reinvented for the AI era.

For data centers, this could reshape cooling norms. For AI startups, it may unlock new performance ceilings. And for engineers and tech developers, it’s a reminder: innovation often lies in rethinking the fundamentals.